Wet Wall Evaporative Air conditioning System

Solan’s facility was originally cooled by 14 individual evaporative air-conditioning units. When looking at the upgrade of this system it was decided to install a solid wet wall construction. 12 months on and after its first summer, the installation has proven to be the right one. Simple in its operation, outside air is drawn through a shade cloth that protects a thrip proof netting and through a wall of plastic air conditioning pads 150 mm thick. This cooled air moves through the plant canopy and is then exhausted via fans on the opposite end of the greenhouse . The environment within has seen humidity levels decrease, reducing the risk of disease whilst improving the growing conditions for the plants and working conditions for staff. Water pumped to feed the pads is gravity fed back to a collection tank from where it is drawn and recirculated through the system.

- Air conditioning inlet. Shade cloth over thrip proof netting.

- Greenhouse Exhaust fans

- Wet wall behind thrip netting

- Interior of air conditioning wall

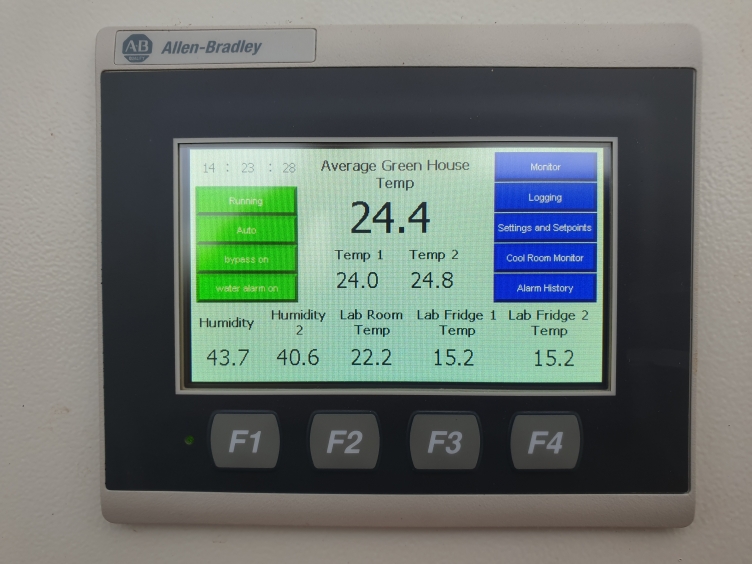

PLC and cloud based communication system

A PLC now co-ordinates the environmental systems within the greenhouse including irrigations, the cool room – monitoring the CO2, O2, temperature and humidity, Solan’s power status from the grid along with the tissue culture laboratory conditions. Should operating parameters move outside their specified limits such as an air conditioner fault, cool room fault, tissue culture laboratory temperature fault – a notification is sent out via a cloud based system to staff.

As data is continuously monitored it has provided the opportunity to log this information which is then available for use in management decisions. As a continually evolving process, new parameters can be added to the system where deemed necessary. The PLC has provided staff the ability to have control systems at hand when not physically on the site. This is invaluable.